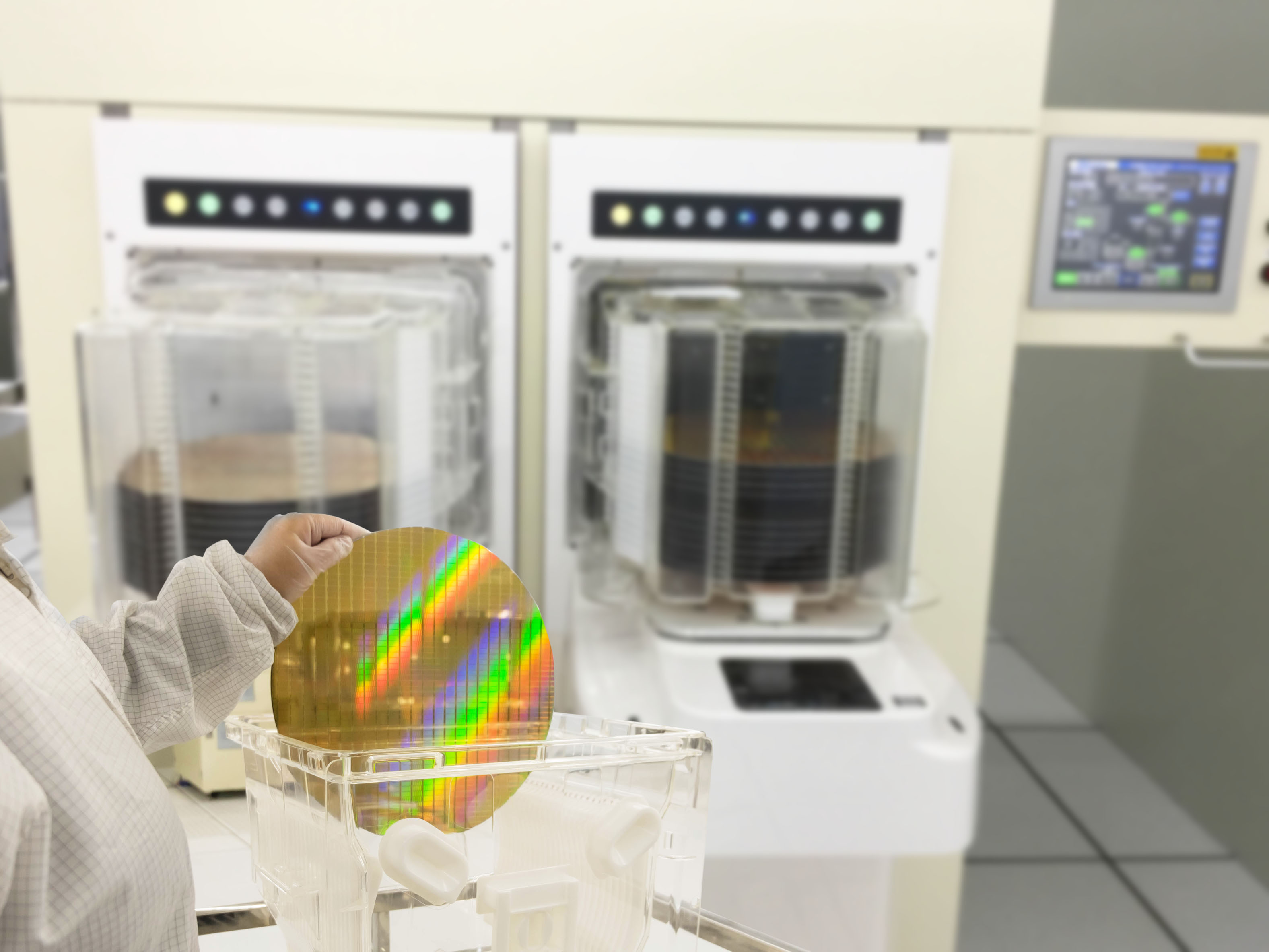

Advancing Semiconductor Packaging Parts and Processes

As efficient semiconductor packaging continues to become increasingly crucial to chip performance, chip manufacturers must account for a variety of complex challenges. These solutions must accommodate increased device complexity while also reducing the dimensions of the overall package. Semiconductor packaging OEMs must develop innovative parts that are both small and strong to offer maximum protection and functionality.

Syensqo's broad portfolio of materials for semiconductors allows for the creation of resistant, durable, stable and smooth packaging solutions. We offer high-performance products, enabling the production of effective trays and polishing tools that allow for advanced protection of semiconductor components.

High-Performing Materials for Packaging Components

To provide manufacturers with the highest-quality materials, Syensqo engineers solutions that offer high strength and excellent resistance to heat and chemicals, ensuring that each chip is protected as it progresses through the packaging process. Halar® ECTFE improve epoxy molding processes, Veradel® PESU and Udel® PSU improve IC trays and Torlon® PAI, KetaSpire® PEEK and AvaSpire® PEAK offer an exceptional solution for FC BGA and high temp trays.

Sophisticated Solutions for Semiconductor Packaging Applications

Mold Release Film (MRF)

For epoxy molding processes, Mold Release Film (MRF) requires excellent heat resistance and releasability so that chips can be effectively released from the heated mold. Halar® ECTFE protect the package from cracking during mold release and reduce downtime by preventing burrs or flash from forming on the mold surfaces.

IC Tray

In semiconductor packaging, IC trays in a variety of shapes and sizes are used for inspection and transport. Veradel® PESU and Udel® PSU offer enhanced physical and thermal protection for electronic devices.

Flip Chip Ball Grid Array (BGA)

The flip chip ball grid array (FC BGA) must be increasingly thinner, smaller, and flatter to meet increasingly stringent demands of flip chip processes.

Torlon® PAI, KetaSpire® PEEK and AvaSpire® PEAKhave low thermal expansion, which prevents the cracking and breaking of thin, vulnerable parts. Both of these materials are incredibly strong and robust, making them outstanding solutions for FC BGA.

High Temp Tray

High temp trays in semiconductor packaging require excellent chemical and thermal resistance as well as antistatic properties. Torlon® PAI, KetaSpire® PEEK and AvaSpire® PEAK meet the needs of this demanding application.

Explore all products for Semiconductors