PSU is the acronym for Polysulfone. PSU is part of Sulfone polymers, which are high performance polymer exhibiting very attractive properties such as high temperature performance, good chemical resistance, outstanding toughness, excellent colorability and very good dimensional stability. As the other sulfone polymers, PESU is an amorphous polymer and displays therefore very good creep resistance, isotropic thermal and mechanical properties (if non-reinforced) and transparency properties. PSU is used in various applications including plumbing, food services, medical, aerospace, wire & cable, etc.

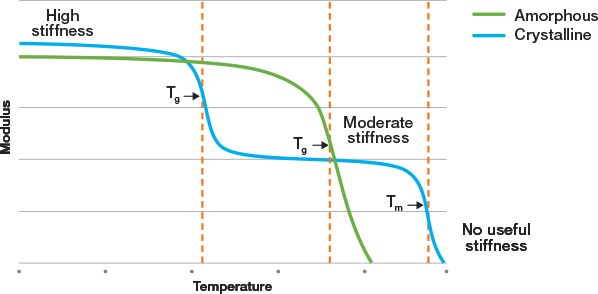

Polymer materials can be divided in two different families depending on the level of molecular organization of the constitutive chains at the microscopic scale.

In semi-crystalline polymers, the molecular chains can locally fold and stack one of each other creating small crystals. The morphology of semi-crystalline polymers consists in crystalline domains surrounded by an amorphous phase, in which the polymer chains are tangled randomly. Due to the presence of crystals, semi-crystalline polymers are generally opaque and display non isotropic properties. They have two different thermal transition : i) the glass transition temperature corresponding to the softening of the amorphous phase and ii) the melting point corresponding to the melting of the different crystals and the flow of the material.

The performance of semi-crystalline polymers is directly related to the degree of crystallinity, i.e. the relative percentage of crystalline phase and amorphous phase and to the size of the crystalline domains. Those factors are intimately related to the polymer nature and to the used processing/molding parameters (applied shear, cooling rate, etc.).

Amorphous polymers present a glass-like structure in which the polymer chains are tangled randomly without any specific arrangement. Those polymers are generally transparent and present isotropic properties. They have no melting point or temperature but rather soften over a range of temperature around the glass transition temperature, Tg. Like glass, amorphous polymers are highly sensitive to stress cracking. Typical amorphous polymers are polystyrene (PS), polycarbonate (PC), polyetherimide (PEI) or sulfone polymers (PSU, PESU and PPSU).

Glass transition temperature Tg of PSU is equal to 190°C

Udel® PSU commercial offer includes transparent, opaque and glass-fiber reinforced grades in natural and colored resins. In most cases, Syensqo uses its proprietary color technology. Product approvals can change from one color to another. Please contact the Syensqo Specialty Polymers representative for more details or for specific needs.

As most sulfone polymers, PSU Udel® is V0 UL94 and HB UL94 rated for respectively 4.5mm and 1.6mm thickness.

Some Udel® PSU compounds comply with U.S. FDA and European Union (EU 10/2011 and 1183/2012) regulations for use as components of articles intended for repeat use in contact with all types of foods. Certification of each Veradel® grade is generally mentioned on the related Technical Datasheet (link to be added). As regulatory action is an ongoing activity, please contact your Syensqo Specialty Polymers representative for the latest information regarding a specific application requiring agency approval or recognition.

Udel® P-1700 NT11 (natural), P-1700 BK937 (black), P-1700 WH7407 (white), R-5100 GY8057 (gray) and several glass reinforcement Udel® GF-110, GF-120 and GF-130 compounds comply with DW approvals required for use as components of parts in continuous contact with drinking water and plumbing applications. Certification of each Udel® grade is generally mentioned on the related Technical Datasheet. As regulatory action is an ongoing activity, please contact your Syensqo Specialty Polymers representative for the latest information regarding a specific application requiring agency approval or recognition.

Udel® PSU displays a very good chemical resistance to many chemicals including: aqueous systems, caustics, inorganic acids, aliphatic hydrocarbons, detergents and soaps and certain alcohols. In general, the chemical resistance of Udel® PSU is known to be lower than Veradel® PESU and Radel® PPSU material. More details about the chemical resistance can be found in the Udel® design guide (available in hthe "Documents" section) or by contacting directly the Syensqo Specialty Polymers Technical Marketing representative.

Natural color of PSU Udel® is transparent slightly amber.

Since Udel® PSU has an excellent chemical resistance, common solvents are generally useless. In order to dissolve the material, specific and sometimes toxic chemicals can be used such as N, N-dimethylacetamide, N,N-dimethylformamide, Chlorobenzene, N-methylpyrrolidone, Tetrahydrofuran, 3-Methylsulfolane or tetrachloroethane. As mentioned, some of those solvents are toxic. Please read carefully the associated MSDS prior handling. Please contact the Syensqo Specialty Polymers Technical Marketing representative for more details.

As for many other polymers, resistance of Udel® PSU to UV depends strongly on the wavelength of the incident UV radiation as well as on the exposure time. Long term exposure of Udel® PSU to direct sunlight results in significant decrease of material ductility. A decrease of the tensile elongation at break and of impact strength can be observed. UV radiation will also modify the material color. Color change appears prior loss of ductility. However it has been proven that UV radiations do not affect other mechanical properties such as tensile strength or young’s modulus. Several applications including direct exposure to UV light can be reported such as visors, lenses, transparent covers, etc. Samples are available for further testing. Please contact the Syensqo Specialty Polymers Technical Marketing representative for more details.

Udel® PSU material displays a good resistance to the most common sterilization methods including steam, EtO, gamma, plasma and chemical sterilizations but exhibits a lower resistance than Radel® PPSU material. Except PPSU, Udel® PSU has better retention of mechanical properties than amorphous transparent polymers including PEI, PC or PS. The material can withstand to repeated sterilization cycles and is therefore particularly recommended for use in medical applications. For more data, please contact the Syensqo Specialty Polymers Technical Marketing representative.

Design of a new part must take into account two different points.

First, the maximum stress level and deflection created in the part during use must remain lower than the corresponding appropriate material property, i.e. tensile, compressive, or shear strength. This will allow deciding whether the initial design incorporates a sufficient safety factor to be viable or whether the design should be modified by changing wall thickness or incorporating ribs or contours to increase the section modulus. Special attention must be paid to parts submitted to tensile stress. In any cases, the design stress should stay below the yield strength of the material.

Secondly, as already mentioned, Udel® PSU is sensitive to stress cracking. Therefore, stress concentrations areas, which may lead to premature failure under impact, creep or fatigue should be avoided. Therefore, inside corner radii should be equal to half of the nominal wall thickness. A fillet radius of 0,8mm (0.032 in.) must be considered as minimum in any case. Outside corners should have a radius equal to the sum of the radius of the inside corner and the wall thickness to maintain a uniform wall thickness.

More details can be found in the Udel® design guide (available in the "Documents" section) or by contacting Syensqo Specialty Polymers Technical Marketing representative.

A quick molding guide is available on the web site for operators at production site. For more detailed information, please refer to the complete Sulfones processing guide (available in the "Documents" section).

Gates must be of adequate size and shape to avoid high residual internal stresses and to allow part filling without the use of extremely high injection melt temperatures or pressures. Voids or sink marks may be caused by gates that freeze off before packing is complete. Gate diameter corresponding to 50% of part wall thickness is recommended. More precise information can be found in the Udel® processing guide (available in the "Documents" section).

In order to guarantee a low level of residual internal stresses in the molded parts and to avoid premature part failure during use, it is mandatory to mold Udel® PSU at a minimum temperature of 140-150°C measured directly at the tool surface.

As Udel® PSU must be molded at a minimum temperature of 140-150°C, conditioning tool system based on circulating oil are recommended. Such high tool temperature is generally difficult to achieve and to control using pressurized water systems. Use of insulation plates is also highly recommended.

Inadequate venting may result in the gas being compressed in the cavity, which may then heat up to the point of causing burn marks on the part and a deposit on the mold surface. Poor venting may also result in poor weld line strength and the inability to completely fill the cavity. Recommended total volume of vents should be equal to about 25% of the cavity perimeter. Venting below the parting line can be accomplished by incorporating vents at ejector pins. Recommended standard vent dimensions can be found in the Udel® processing guide (available in the "Documents" section).

The following tool steels are recommended for molding PSU material: DWN 1,2767 ; 420 Stainless Steel or High Density Chrome Plated S-7 steel. Equivalent steel reference in terms of composition are also accepted.

Udel® PSU as other sulfones polymers can react at high temperature with the steel of the injection unit through a reaction known as sulfidation. Sulfidation is a chemical reaction leading to the creation of iron sulfide (noted as Fe + S = FeS) that occurs whereby unprotected steel reacts at processing temperatures with sulfur that’s liberated during the processing of sulfur containing polymers like sulfones polymers. Sulfidation can occur on the inside of the injection molding machine screw/barrel assembly and/or within a hot runner system. Sulfidation reaction produces a very thin, brittle film of iron sulfide (deep black in color) on the surface of the steel which is easily removed by injection pressure. The thin black film that’s removed is pushed (or injected) into the molded part, causing small black “chip-like” specks or thin grey “smoky” appearing traces. Experience has shown that use of steel containing at least 20% chromium or an additive package based on Stellite® can dramatically improve corrosion and delay sulfidation. The use of highly nickel-based alloys should be avoided. More details about sulfidation can be found in the Handling Suflidation technical bulletin.

Use of hot runners is generally not recommended for molding Udel® PSU. However parts can be successfully molded if precise recommendations are followed including no internal heating, precise temperature control … More details can be found in the Udel® processing guide (available in the "Documents" section) or by contacting Syensqo Specialty Polymers Technical Marketing representative.

Udel® PSU is an amorphous polymer and is therefore very sensitive to stress cracking. In order to prevent risk of premature failure, it is important to minimize the level of residual internal stresses or molded-in stresses when working with fabricated sulfone parts. A procedure has been developed for estimating the magnitude of the residual internal stresses. The procedure entails exposing the parts to a series of chemical mixtures. The stress level required for crazing to occur for each mixture was determined using specimens at known stress levels. Contact your Syensqo Specialty Polymers representative for more details.

The level of residual internal stresses in molded parts depends on different factors such as part design, thickness, and tool design or injection conditions. However, a maximum level of residual internal stresses of 5MPa for Udel® PSU molded parts can be considered to be acceptable in most cases. Contact your Syensqo Specialty Polymers representative for more details about the procedure and the targeted level.

The desired moisture content for injection molding is below 500 ppm (0.05%) and for extrusion below 100 ppm (0.01%). Hopper drying requires sufficient insulation and minimal system leakage. Inlet air temperature must be high enough to maintain a polymer pellet temperature of at least 135°C (275°F), and the dew point of the inlet air should be -40°C (-40°F). These conditions must be sustained long enough for the polymer moisture content to drop to below the minimum levels suggested for the processing technique to be used. Recommended drying times and temperatures for Udel® resins are: 4 hours at 135°C (275°F)

Samples pellets for molding trials and several shapes of molded articles can be supplied for testing purposes. There is a wide range of products and sample types available. Stock shapes or other thick walled semi-fabricates for machining prototype parts for example, are not offered due to the complexity of the practical aspects to cool such parts fast enough and prevail the material from being degraded at the inner core of thick sections. Please consult your Syensqo Specialty Polymers representative for further information or sample requests.

Precise information about start-up, shutdown and purging procedure can be found in the Udel® processing guide (available in the "documents" section) or by contacting Syensqo Specialty Polymers Technical Marketing representative.

Most of Udel® PSU grades are fully characterized to run FEA analysis or rheological analysis. Data are openly available in most of Commercial Rheological Softwares (Moldflow, Moldex, CADFlow, etc.). Please contact your Syensqo Specialty representative to help in your development work.

You can find a list of datasheets on the Udel® PSU page or visit the technical datasheets library.

Material Safety Datasheet can be obtained by contacting Syensqo Specialty Polymers technical marketing representative.