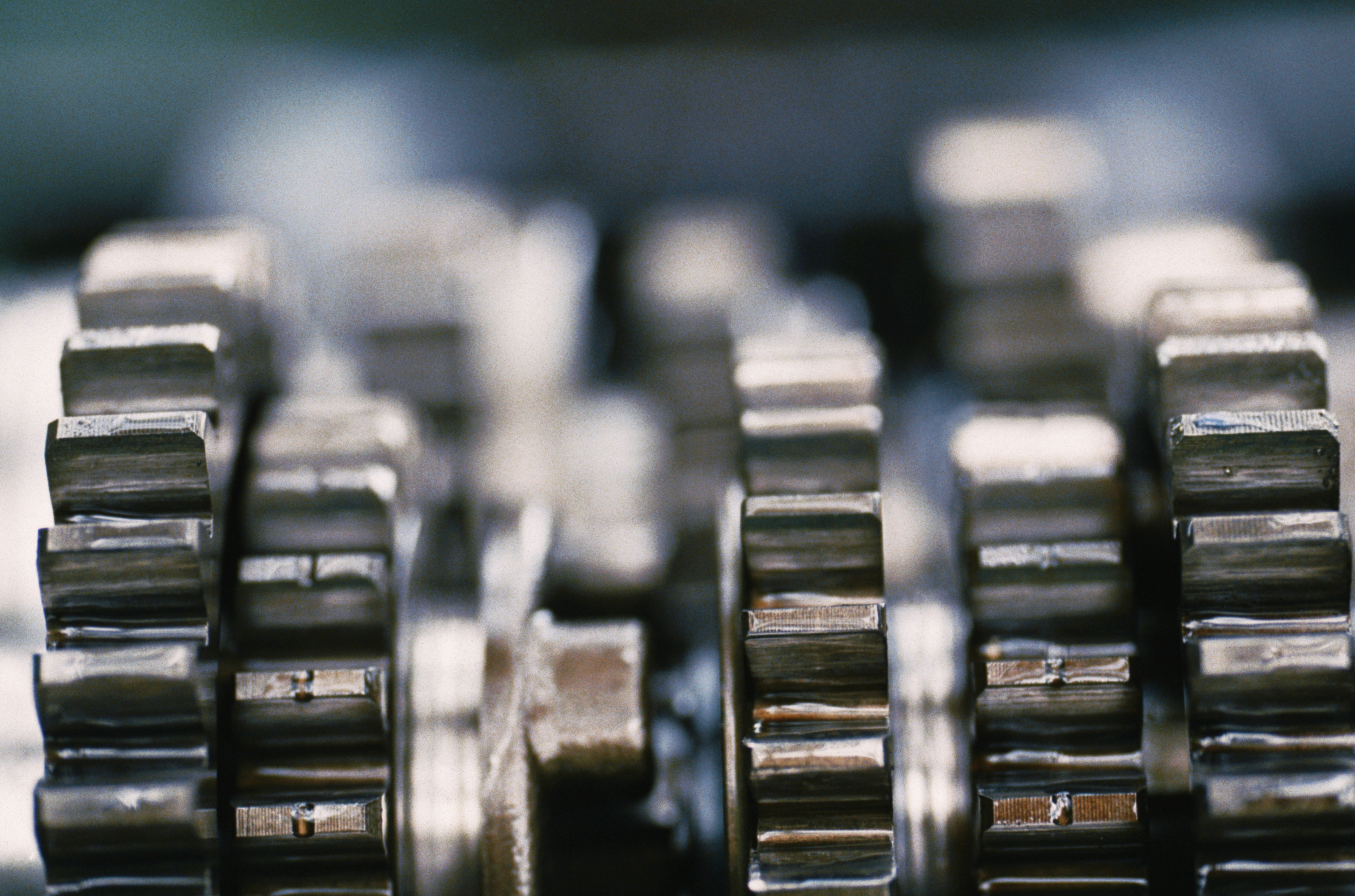

Advanced Components for Optimized Metal Treatment Processes

Effective metal treatment is critical to manufacturing reliable solutions in a wide range of industries, from automotive and construction applications to general industry products. Formulators must utilize high-performance additives to optimize metal treatment processes, including cleaning and degreasing, conversion, passivation and electroplating.

Cleaning and Degreasing

Pre-treatment cleaning processes are critical to achieving reliable, high-performance metal treatment. Advanced metal cleaning and degreasing additives remove dirt, grime, impurities, oils and intermetallic particles from metal surfaces for optimal paint adhesion and anti-corrosion benefits. Syensqo's additives for metal cleaning and degreasing address the need for more environmentally friendly solutions and are adaptable to new oils.

Conversion

Conversion processes provide a coating that promotes improved corrosion resistance, organic coating adhesion or both. Specialty formulations developed with advanced additives facilitate enhanced paint adhesion and corrosion resistance. Syensqo's additives, especially the Addibond® Range, improve these essential performance features with additional benefits like non-toxic, sludge-free conversion.

Passivation

This optional post-treatment stage can boost paint adhesion and corrosion resistance while also reducing rust on commonly used metals. The AddibondTM Range is an optimal additive for passivation treatments and sealing, and it can be used without altering existing passivation processes.

Electroplating

Electroplating in metal treatment forms a thin organic coating on an electrode to boost corrosion resistance and produce a desirable surface finish. Syensqo's portfolio includes leveling agents for electroplating and wetting agents compatible with high-electrolyte environments. These solutions are formulated to contribute to high-quality

Explore all products for Metal Treatment