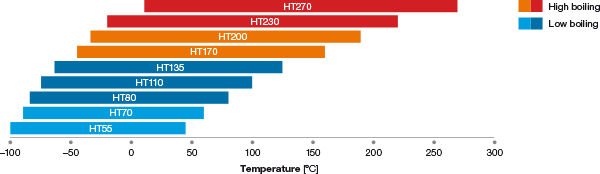

Galden® HT heat transfer fluids have boiling points ranging from 55°C to 270°C (131°F to 518°F), which is broader than other commercial fluorinated heat transfer fluids. Boiling points of High Boiler (HB) grades range from 170°C to 270°C (338°F to 518°F), which enables Galden® PFPE to be used at end-use temperatures up to 290°C (554°F).

Suggested operating temperature ranges are summarized below. The lower limit is set when the fluid viscosity reaches 20 cP (11-12 cSt), which is the typical operating range of many commercially available fluid pumps. The upper limit is set at 10°C (18°F) below the boiling point of the fluid itself.

Suggested operating temperature range

Pour point is the lowest temperature at which a fluid will flow. Galden® HT fluids offer a wide variety of very low temperature pour points, ranging from −66°C to −115°C (−76°F to −175°F). A rule of thumb when selecting fluids is to ensure that the pour point is at least 10°C (18°F) lower than the lowest anticipated ambient temperature.

The density of Galden® PFPE fluids ranges from 1.66 to 1.86 g/cm3 at 20°C (68°F).

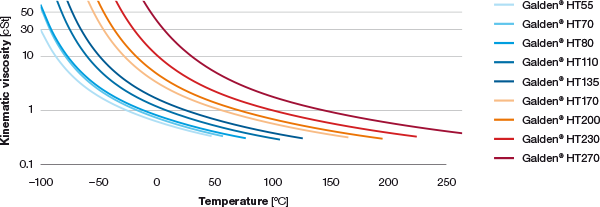

Viscosity is a measure of a fluid's resistance to flow, which generally decreases as the temperature increases and increases as the temperature decreases. For many heat transfer applications, the lower temperature limit (pumpability limit) is set when the fluid viscosity reaches the value of 20 cP (11 – 12 cst).

Kinematic viscosity vs. temperature

Galden® PFPE fluids are not flammable as they have no flash, fire or auto-ignition points. These non-hazardous materials are Factory Mutual Underwriters approved and compliant with FM Standard 6930 for fluid safety.

Galden® PFPE fluids are stable in thermal conditions above 300 °C. In the presence of oxygen, however, the operating temperature is lowered to 290°C (554°F). Up to these temperatures, decomposition of the fluids is negligible.

Galden® PFPE fluids do not corrode metals because they interrupt the electrical circuit that is the basis for the corrosion process. The conducting environment for ionic movement is disabled by the high volume resistivity of Galden® PFPE, which does not vary in use. The volume resistivity of DI water is at least 107 ohm·cm, a value that tends to reduce over time as DI water extracts metal ions.

Corrosion in Galden® PFPE heat transfer systems can generally be linked to either a separate water phase or thermal decomposition of the fluid. In order to have a separate water phase, the amount of water in the system must exceed the fluid’s saturation level. The saturation level of water in Galden® PFPE fluids is usually < 20 ppm by weight. Water present in the fluid at or below this level has never been linked to corrosion. Water present above this level means a separate water phase. If such entrained water comes into contact with metal parts, corrosion can occur rapidly.

A fluoride ion can be generated any time the fluid is heated above its decomposition temperature, leading to corrosion. Thermal degradation for Galden® PFPE starts between 290°C to 300°C (554°F to 572°F). HF can be generated only when the fluid is brought above its decomposition temperature, which far exceeds typical operating working temperatures. Corrosion resulting from decomposition is very rare and only observed in systems that have undergone a failure. Examples include: a burned out heater, high voltage discharge in dielectric systems or a burned out electrical component in a direct contact electrical application.

Galden® PFPE fluids have excellent electrical properties, which is a key requirement for many applications. Dielectric strength is 40 kV at 2.54-mm gap. Volume resistivity is 1.5 x 1015 ohm·cm.

The saturation level of water in a Galden® PFPE fluid is usually < 20 ppm by weight.

General guidelines for the compatibility of Galden® PFPE fluids are summarized below.

Metals | Plastics | Elastomers |

|---|---|---|

AISI 316, Copper, Brass, Iron, Nickel, Aluminum, Stainless Steel, Bronze | LDPE, PP, PC, ABS copolymers, | Butyl Rubber, Natural Rubber, Silicone Rubber, NBR, EPDM, Fluorosilicone |

You can select a heat transfer fluid based on two main parameters. The first is viscosity at the lowest operating temperature. This is typically < 20 cp ( 11-12 cSt) for fluorinated fluids for pumpability. The second is vapor pressure at the highest operating temperature. The boiling point of the fluid should be at least 10°C (18°F) higher than the highest operating temperature in order to avoid excessive pressure in the HT circuit, decrease fluid loss and reduce cavitation.

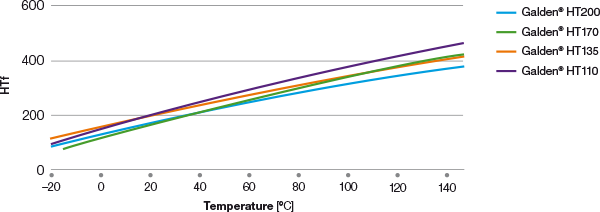

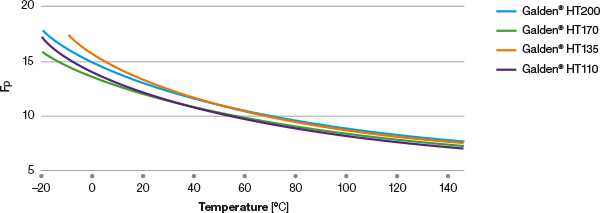

Heat transfer performance can be predicted by using the Heat Transfer Factor (HTf) and Pressure Drop Factor (Fρ). Both factors are functions of fluid properties and are subjected to change with temperature. A plot of HTf and Fρ vs. temperature can be used to compare fluids with the same TCU geometry and flow conditions.

Heat Transfer Factor (HTf): HTf = 0.023 · k 0.67 · (r ·cp) 0.33 · n – 0.47

Where:

k = Thermal conductivity

r = Density

cp = Specific heat

n = Kinematic viscosity

HTf compares the fluid’s capacity to add or remove heat under fully developed turbulent flow conditions (Re > 10,000) for a given geometry. The higher the HTf, the better the heat transfer efficiency.

Pressure Drop Factor (Fρ): Fρ = 0.092 · ρ · ν 0.2

Where:

ρ = Density

ν = Kinematic viscosity

When fluid flows through a pipe there will be a pressure drop that occurs as a result of resistance to flow. A lower Fρ relates to reduced frictional loss, given the same fluid velocity and tube geometry. A higher Fρ indicates that more pumping power is required.

For Galden® PFPE fluids, we recommend using a heater watt density ≤ 4 ÷ 5 W/cm2 in order to avoid instability in the heater surface temperature for low flow units (i.e. fluid reservoir in the TCU). Higher watt density heaters can be used if the heater section is located where the fluid flow is near the pump outlet.

We recommend 4 W/cm2 (critical breakdown occurs around 14 W/cm2). The decision to go beyond this level should be made by the customer.

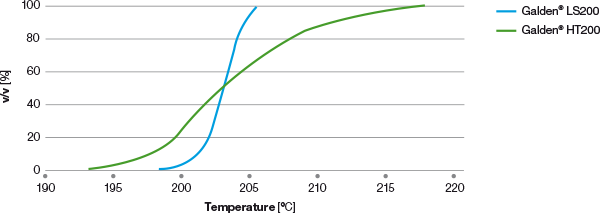

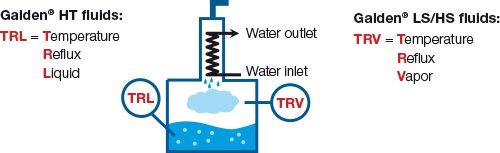

Galden® LS/HS fluids are specifically designed for the Vapor Phase Soldering (VPS) process used to mount chips to printed circuit boards. A narrow molecular weight distribution and precise vapor temperature control are critical to this application. These properties are monitored by measuring distillation range (ASTM D1078) and boiling temperature (TRV ASTM D1120). Both properties are always included in material specifications.

Boiling point is the temperature at which the vapor pressure of the liquid equals the environmental pressure surrounding the liquid (ASTM D1120). Temperature Reflux Liquid (TRL) relates to Galden® HT fluids, whereas Temperature Reflux Vapor (TRV) relates to Galden® LS/HS fluids.

Select Galden® PFPE grades are NSF approved based on related intended uses:

| H1 | General, incidental contact |

| HT1 | Heat transfer fluids, incidental contact |

| HTX1 | Ingredients for use in HT1 heat transfer fluids |

| HX1 | Ingredients HX1 for use in H1 lubricants, incidental contact |

Yes, Galden® PFPE fluids satisfy MIL requirements. Thermal shock testing is performed according to MIL STD 883 method 1011 or MIL STD 202 method 107. Hermetic seal testing is performed according to MIL STD 883, method 1014K; MIL STD 750, method 1071; and MIL STD 202, method 112.

MIL Property Standards for Testing Fluids

| Property | Value |

|---|---|

| Appearance | Clear, colorless |

| Density, 25 °C | > 1.6 gm/cm3 |

| Dielectric strength, 2.54-mm gap | > 30 kV |

| Viscosity profile | According to the equipment manufacturer |

| Residue | < 50 ppm |

| Composition | No chlorine, no hydrogen* |

*This is not a standard and the use of products having chlorine or hydrogen is allowed.

When stored in their original sealed containers, Galden® PFPE fluids are chemically stable for over 20 years.