Fluid & Gas Handling Applications

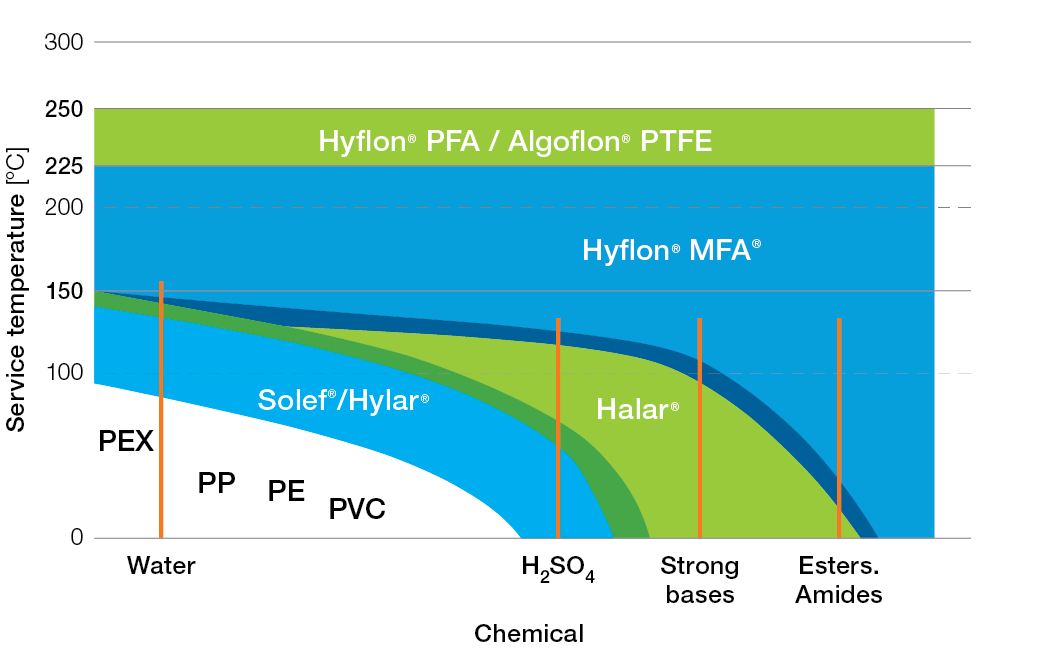

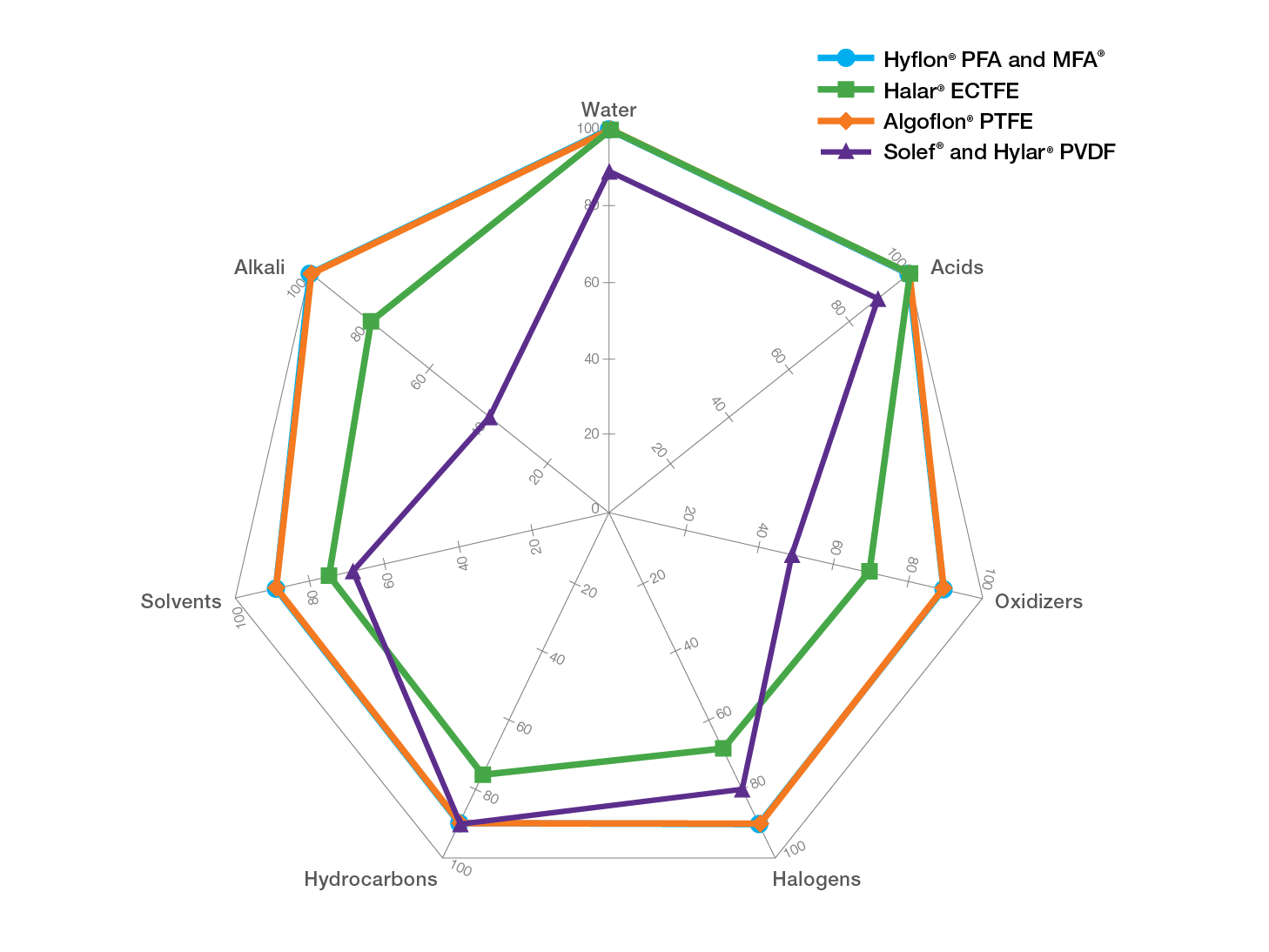

Fluorinated plastics Halar® ECTFE, Solef® PVDF, Hyflon® PFA/MFA® and Algoflon® PTFE, are ideal when excellent temperature and chemical resistance are required. Extruded or molded components include tubes, pipes, hose, column packing, pumps, valves, fittings, gaskets and expansion joints. Small items can economically be made entirely of fluoropolymers. Certain heat exchangers, used in very acidic media, have entire components made of Hyflon® PFA or MFA®.

Hyflon® MFA®

The Hyflon® MFA® surface is up to 5 times smoother than standard PFA, improving cleanliness, reducing pressure drop, and reducing wall build up in problematic slurries or mixtures. It is designed to give much better physical properties than FEP, lower creep and improved stress cracking resistance. Like PFA, Hyflon® MFA® offers the highest temperature rating and broadest chemical resistance of all melt processable fluoropolymers. MFA® has a continuous use temperature of 225°C.

Solef® PVDF

Thanks to their unique properties mix, PVDF have a large variety of applications. In the chemical industry PVDF is also often used as protective linings against corrosive chemicals for pump bodies to convey corrosive fluids. We can also find pressure piping systems in PVDF which are in most cases welded. Situated between chemical industry and domestic piping, chemical waste piping is another important application of PVDF. In other industries, purity is the key property. This is the case of the pharmaceutical industry, where the intrinsic purity and chemical resistance of PVDF piping systems are well appreciated.

Halar® ECTFE

Halar® ECTFE coatings are recommended for high purity fluid systems in the chemical industry, particularly where the process surface must be smooth, pure (low extractables), and chemically resistant. Halar® ECTFE powder coatings are used in the presence of extremely aggressive chemical environments. Moreover, the extremely smooth and chemical resistant surface of Halar® ECTFE prevents microbial growth.

Algoflon® PTFE

Outstanding chemical inertness in aggressive environments, thermal resistance, electrical properties, and non-stick characteristics in a wide range of temperatures from cryogenic to 260°C. This makes Algoflon® PTFE the ideal material for many critical applications. In particular, Algoflon® DF powders are currently used for the production of pipe and tubing by paste extrusion meeting the demanding requirements of the chemical industry.

Multilayer Pipes

Solef® PVDF

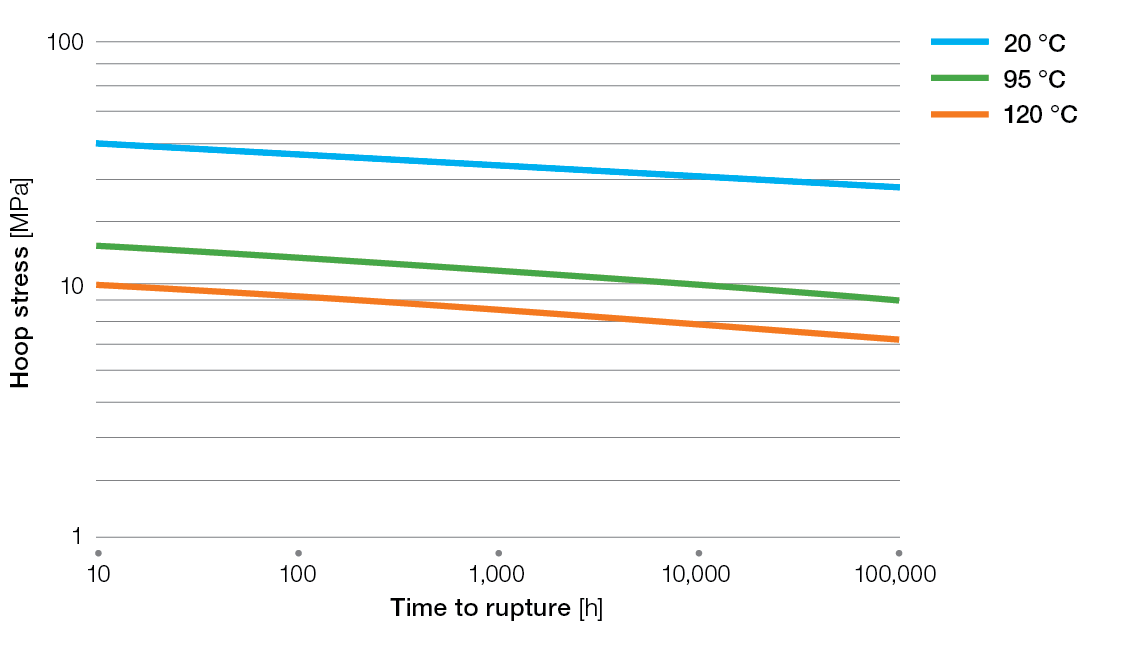

Solef® PVDF is a semi-crystalline, melt-processable fluoropolymer that offers excellent resistance and barrier properties to many chemicals combined with exceptional fatigue resistance and long-term hydrostatic strength. It has been used successfully in the chemical industry for more than 30 years. Solef® PVDF has also been used for decades in the semiconductor and oil & gas industries as well as for domestic plumbing systems.

Key features

- Excellent resistance to chemicals, in particular to acids

- Outstanding long-term hydrostatic strength

- Exceptional fatigue resistance

- Good barrier properties against a broad range of chemicals

- UV resistance for outdoor applications

- Resistant to flame propagation

Moreover Syensqo can offer compounds for chemical industry applications, for Gas and Fluid transport and industrial applications.

Performance Data

Fluoropolymer chemical resistance and temperature rating

Chemical | Formula | Concentration | Maximum Temperature (°C) |

| Inorganic Acids | |||

| Hydrochloric | HCl | 37% | 140 |

| Nitric | HNO3 | 50% | 100 |

| 65% | 75 | ||

| Sulfuric | H2SO4 | 80% | 125 |

| 97% | 23 | ||

| oleum | not resistant | ||

| Bases | |||

| Ammonium hydroxide | NH4(OH) | 30% | 23 |

| Sodium hydroxide | NaOH | 50% | not resistant |

| Hydrocarbons | |||

| n-Hexane | CH3(CH2)4CH3 | 100% | 140 |

| Toluene | C6H5CH3 | 100% | 100 |

| Alcohols | |||

| Methanol | CH3OH | 100% | 50 |

| Ethanol | CH3CH2OH | 100% | 100 |

| Organic acids, esters and ketones | |||

| Acetic acid | CH3COOH | 100% | 50 |

| 50% | 75 | ||

| Acetone | CH3COCH3 | 100% | not resistant |

| 5% | 75 | ||

| Classic polymer solvents | |||

| Dimethylformamide | CH3CON(CH3)2 | 100% | not resistant |

| Dimethylsulphoxide | CH3SOCH3 | 100% | not resistant |

| Halogenated solvents | |||

| Chlorobenzene | C6H5Cl | 100% | 50 |

| Chloroform | CHCl3 | 100% | 50 |

| Amines and nitriles | |||

| Acetonitrile | CH3CN | 100% | not resistant |

| Aniline | C6H5NH2 | 100% | 50 |

| Peroxides | |||

| Hydrogen peroxide | H2O2 | 30% | 50 |

| Fluids used in the automotive industry | |||

| Crude oil | 100% | 140 | |

| Mineral oil | 100% | 140 |

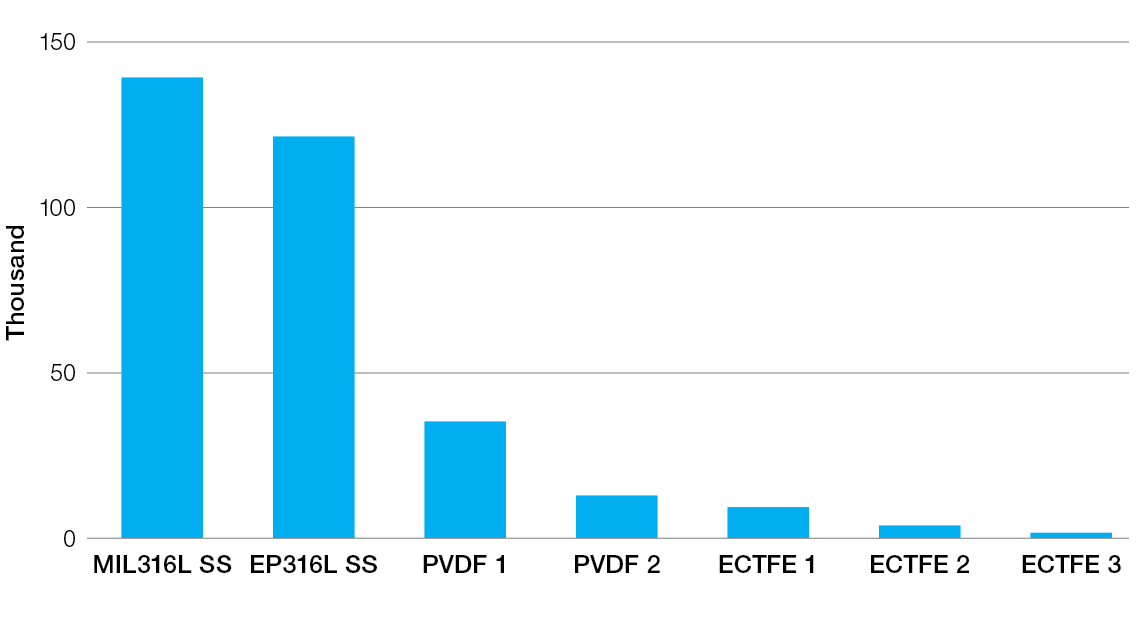

Highest Cell Count/cm2 - Flow Velocity at 3

Solef® PVDF Hydrostatic Resistance

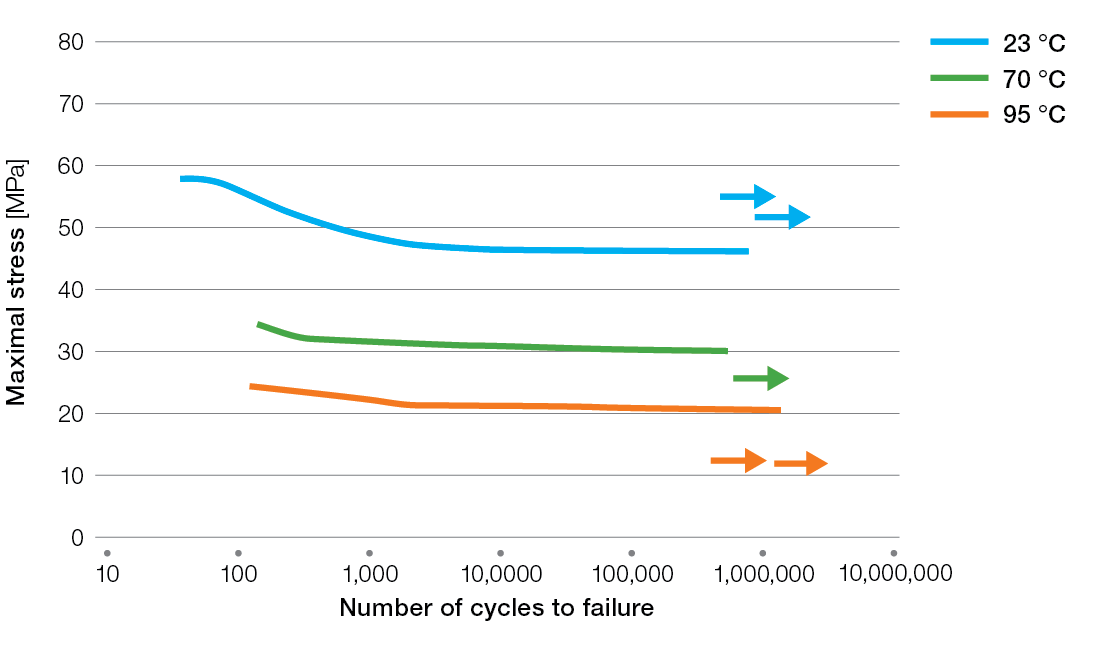

Sinus 1 Hz - R = 0.1 - Controlled by force - Sample ISO1

Fluoro- and Non Fluorinated Bursting Resistance (@ 23°C and 100°C)

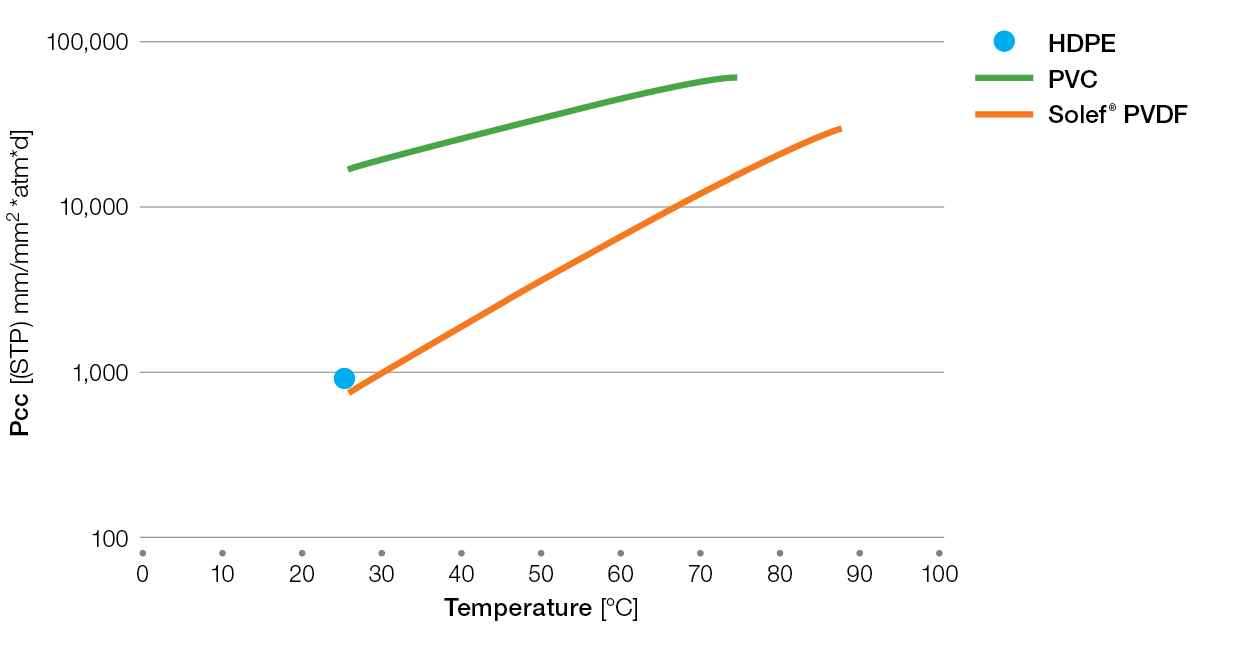

Water permeability

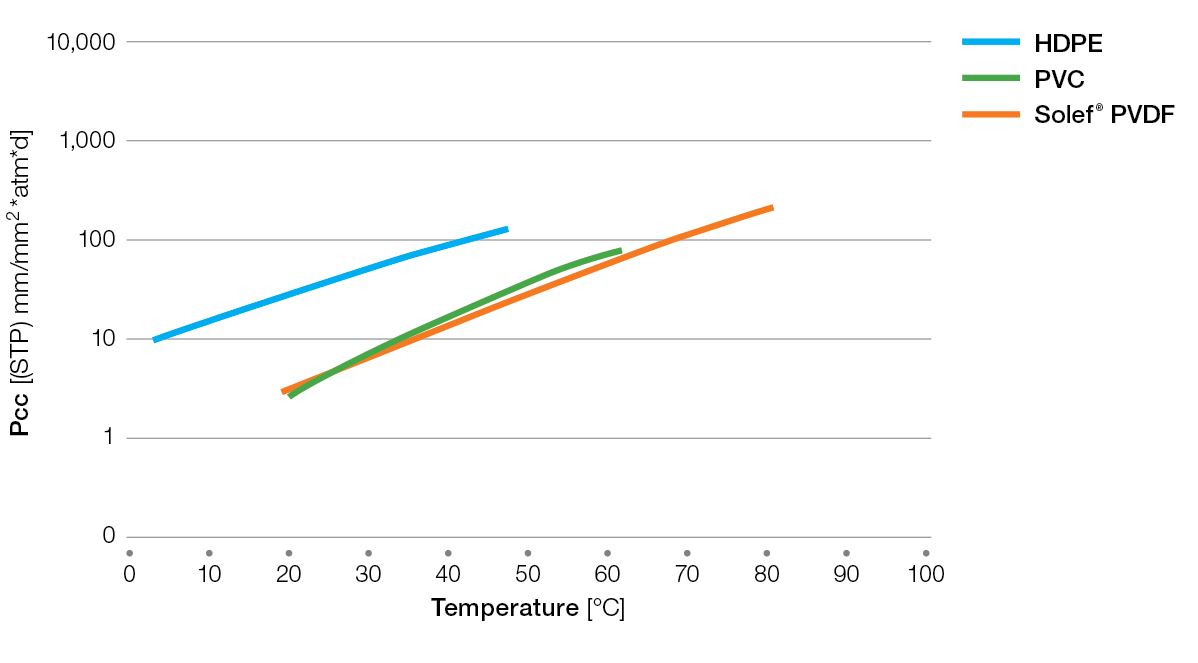

Oxygen permeability

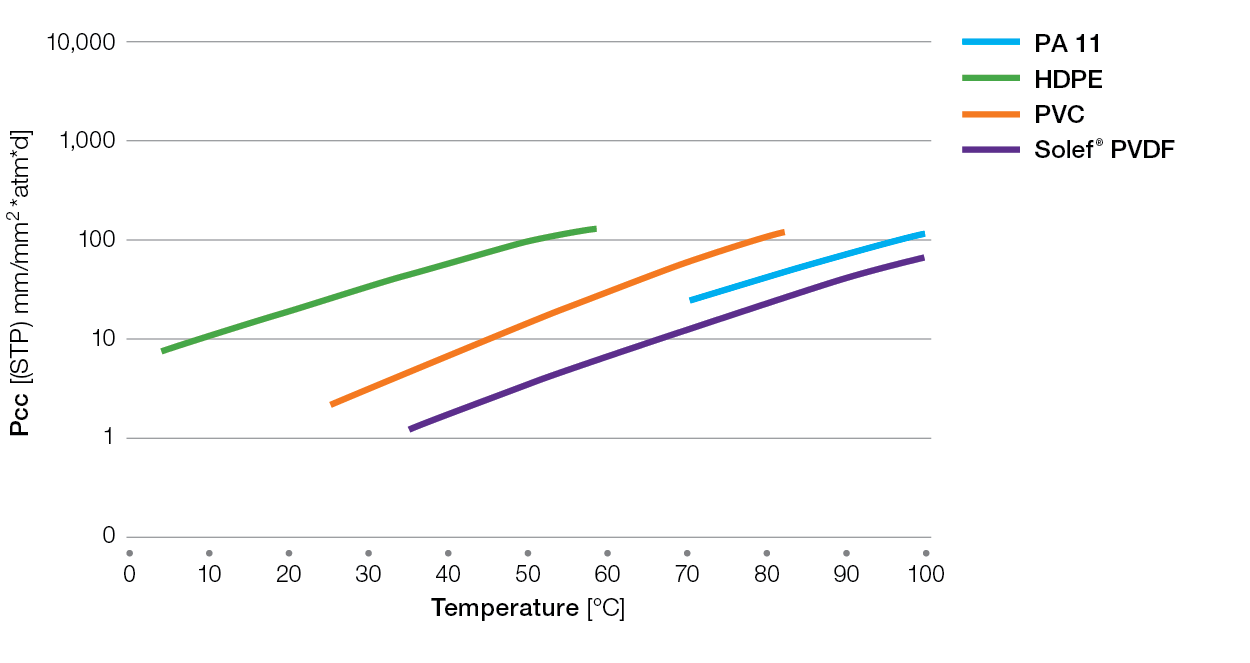

Methane permeability

| Initial Properties | ||

| UL 94 Flame test class | V-0 | |

| Tensile impact test [kJ/m2 (ft∙lbf/in2)] | 81 (38.5) | |

| Tensile strength [MPa (psi)] | 45 (6,525) | |

| Percent retention after conditioning | ||

| 1000 h UV | UL 94 Flame test class | V-0 |

| Tensile impact test | 99 | |

| Tensile strength | 100 | |

| 7 days water @ 70ºC (158ºF) | UL 94 Flame test class | V-0 |

| Tensile impact test | 100 | |

| Tensile strength | 95 |

Artificial Aging using Xenon-Arc WOM and Water Exposure (UL 746C)

Test conditions

- Solef PVDF 6008 plates - 1 mm thick

- Tensile impact test measured in accordance with ASTM D 1822

- Tensile strength measured in accordance with ASTM D 638

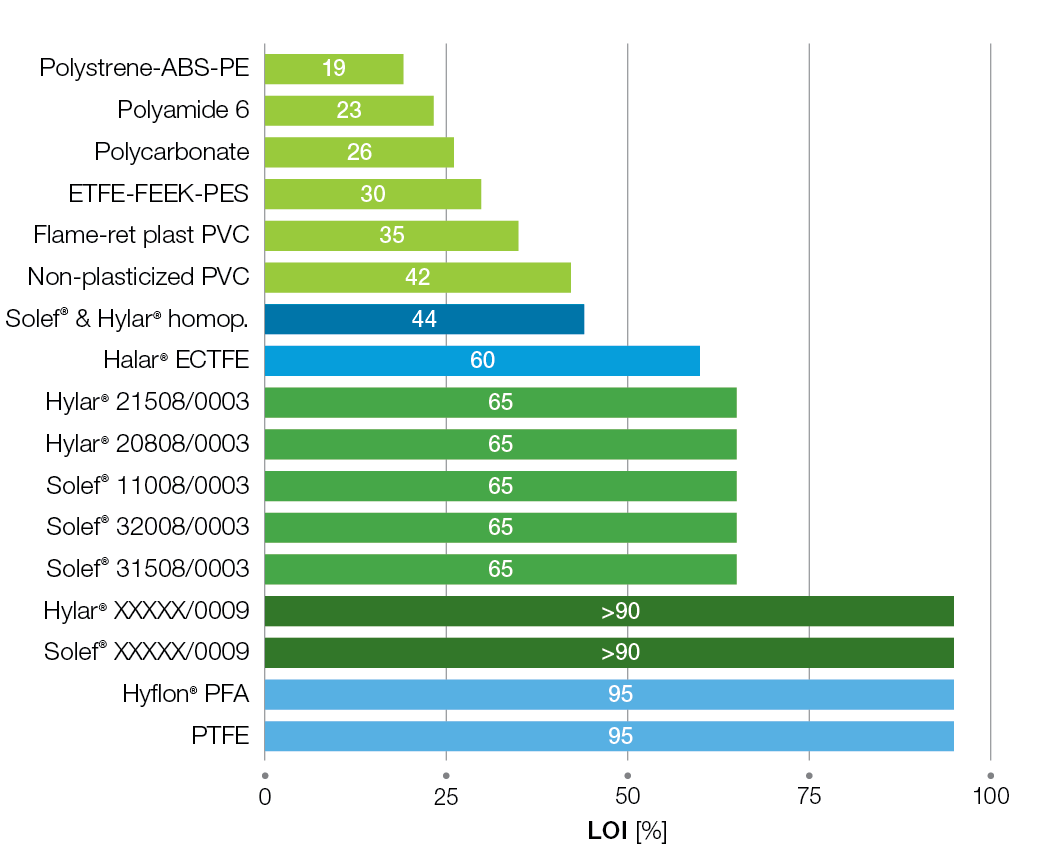

LOI of Solef® and Hylar® PVDF Resins and Various Thermoplastics